The FUTTA III Demonstrator Call continues to support the transfer of fusion technologies to non-fusion applications. The 2023 edition led to the successful demonstration of two innovative projects: one enhancing space propulsion through superconductive inductors, and another enabling direct hydrogen measurement in molten brass alloys. Below are the stories of TOMO and ALMAG, the 2023 demonstrator winners.

TOMO: Superconductive Inductors to Boost Magnetic Propulsion for Satellites

Tomorrow’s Motion GmbH (TOMO), in partnership with Vision Electric Super Conductors GmbH (VESC), implemented a breakthrough demonstrator aimed at increasing the thrust efficiency of TOMO’s propellant-free satellite propulsion system. This system, which relies solely on magnetic forces and electrical power, eliminates the need for propellant, drastically reducing satellite mass and significantly extending mission lifetime.

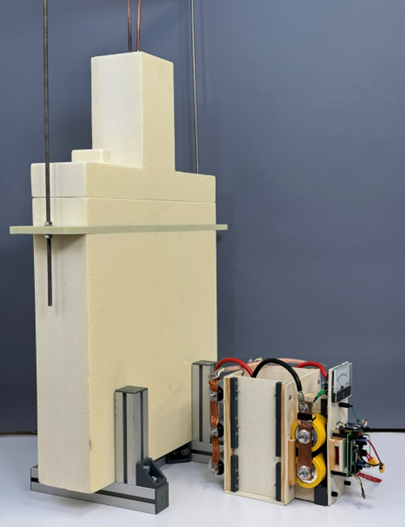

During this project, they explored integrating high-temperature superconductive inductors—familiar from fusion research—into its propulsion drive. These inductors, cooled to achieve near-zero electrical resistance, drastically enhance thrust performance while substantially lowering power consumption. A custom-developed power supply, capable of delivering up to 500 A at just 0.5–2 V, provides the precise current needed to energise the superconductors. This same supply concept has direct relevance for other superconducting applications in fusion research, where stable high-current, low-voltage drivers are key for advanced magnet systems.

During the six-month project, TOMO and VESC designed a new propulsion unit, a high-current driver delivering up to 500 A, and conducted predictive simulations. Experimental testing in 2024, using liquid nitrogen cooling, demonstrated a 26-fold improvement in thrust, with future optimisation pointing toward a 60–100× enhancement. Power consumption was reduced by half, validating the efficiency of the superconducting component. TOMO and VESC co-invested €30k each, recognising the strategic potential of superconducting propulsion for the space industry.

ALMAG: Measuring Hydrogen in Molten Brass Using Fusion Sensor Technology

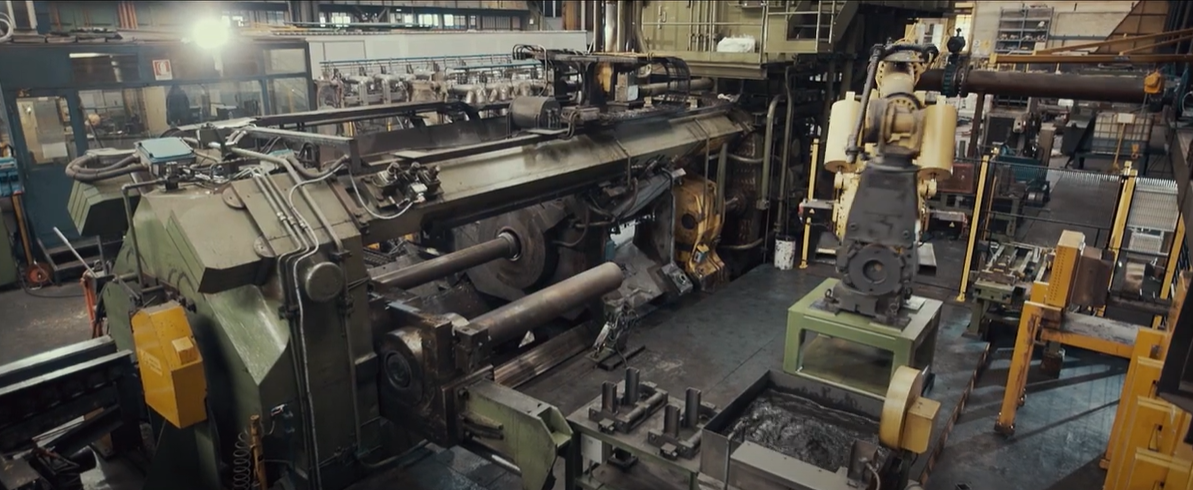

In a cross-sector collaboration between ENEA’s Brasimone Research Centre and ALMAG, a leading European manufacturer of brass bars, a hydrogen permeation sensor originally designed for fusion applications was adapted to molten brass environments. The sensor, initially developed under EUROfusion to measure hydrogen isotopes in Li-Pb, was repurposed to investigate hydrogen’s effect on high-pressure brass components.

Adapting the sensor involved several technical challenges: brass melts at significantly higher temperatures than Li-Pb and exhibits greater chemical aggressivity. New materials were tested to ensure sensor durability, and an inertisation system was developed to maintain an oxygen-free interface during sensor insertion. A dedicated vacuum line connected the sensor to a turbomolecular pump and mass spectrometer, allowing for precise measurement of hydrogen concentration in molten alloy.

Two tests validated the system: a 6-hour trial and a subsequent 30-hour test, both confirming sensor integrity and functionality. This marks the first known direct detection of hydrogen in molten brass and opens pathways for quality control in metallurgy and other industries where hydrogen-induced embrittlement is a concern. Future large-scale testing will further explore the correlation between hydrogen content and product performance under pressure.

The FUTTA III Demonstrator Call continues to act as a catalyst for applied innovation. By enabling focused experimentation and industrial adaptation, it helped unlock promising follow-up opportunities, with partners committing further resources and planning next steps. These results highlight the long-term value of well-targeted technology transfer actions.