The road from fusion energy research to practical industrial applications is often unexpected but highly rewarding. One such breakthrough has emerged from the development of tungsten (W) alloys originally designed for use in fusion reactors. These advanced materials, tailored to withstand extreme conditions, have now found a promising application in corona discharge electrodes, critical for air purification and electronics cooling in aerospace applications.

Under the EUROfusion program, researchers at CEIT-IK4 have engineered a class of W-based alloys aimed at reinforcing the first wall blanket of DEMO fusion reactors. The primary challenge was overcoming tungsten’s susceptibility to high-temperature oxidation, which could lead to the formation of volatile and radioactive oxides above 750°C. By incorporating chromium (Cr) and yttrium (Y) into tungsten through a powder metallurgy process, CEIT developed an alloy with a nanostructured microstructure that forms a stable oxide layer under extreme conditions. This innovation not only improves the safety of fusion reactors but also opens new opportunities for industrial applications beyond nuclear fusion.

CEDRION, a Spanish startup specializing in plasma-based air movement and cooling technologies, identified an opportunity to leverage CEIT’s advanced tungsten alloys for corona discharge electrodes. These electrodes are essential components in electrohydrodynamic devices that generate ion wind—an effect where charged particles accelerate neutral air molecules, creating a directed airflow. This phenomenon is utilized for both cooling electronic components and purifying air in aerospace environments.

Initially, CEDRION’s focus was on developing avionics cooling solutions for Airbus. However, the disruption caused by the COVID-19 pandemic, including the closure of Airbus BizLab and the loss of a key contract, forced the company to pivot towards air purification applications. Seeking to enhance the durability and performance of their corona discharge electrodes, CEDRION collaborated with CEIT to integrate fusion-derived tungsten alloys into their technology.

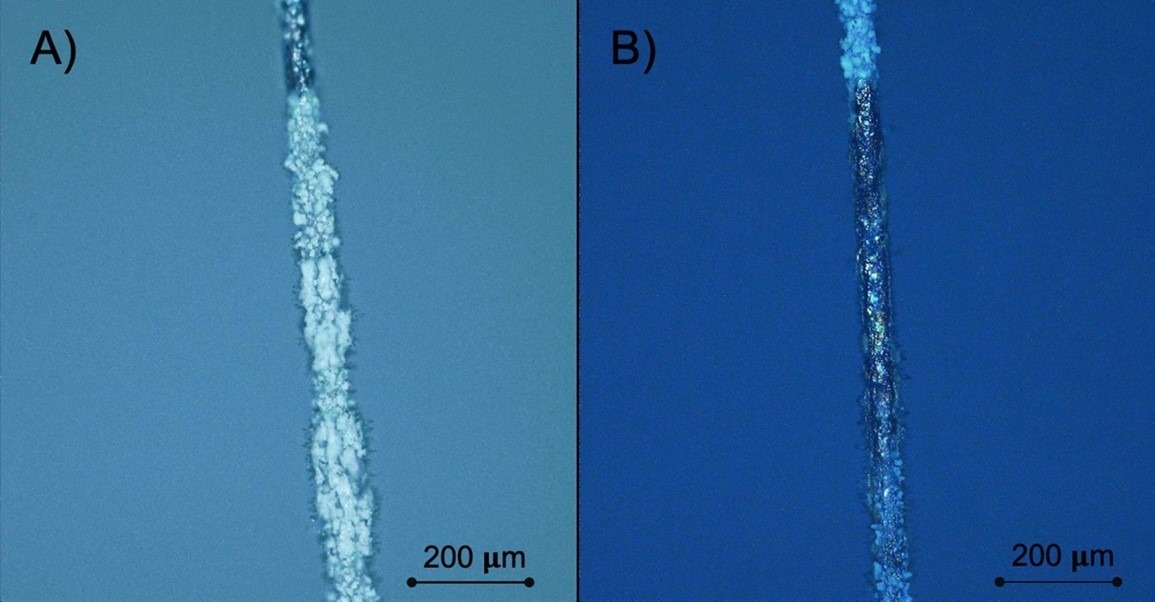

The partnership between CEDRION and CEIT led to the development and testing of prototype electrodes incorporating the novel tungsten alloy. Through rigorous experimentation, engineers analyzed the power variation over time and measured the erosion-oxidation rates of the alloy-based electrodes. The results were highly promising: the new electrodes demonstrated significantly longer lifespans compared to conventional materials. This advancement not only reduces waste associated with frequent electrode replacements but also enhances the reliability and efficiency of air purification and electronics cooling systems.

The success of this technology transfer highlights the far-reaching potential of fusion-derived materials beyond their original intended use. By extending the lifespan of critical components, CEDRION has reinforced its position in the aerospace and air purification sectors, offering improved solutions for cleaner air and more efficient electronic cooling. Meanwhile, for CEIT and the broader fusion research community, this application provides valuable insights into the commercial viability of their materials.

This collaboration stands as a testament to the impact of scientific innovation, proving that breakthroughs in fusion research can fuel advancements across industries, creating tangible benefits for society.

You can also get in touch with us if you need any support